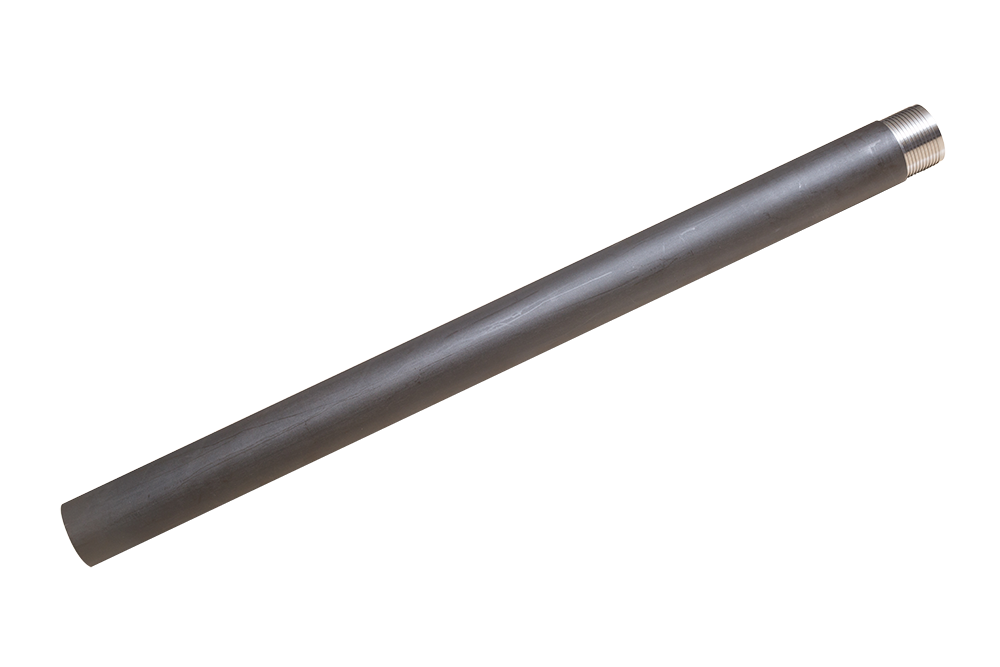

HW va HWT korpusi

| Koson | BW | NW | HW | HWT | PWT | |

| Tashqi diametri OD | mm (dyuym) | 73,03 (2,88) | 88,90 (3,50) | 114,30 (4,50) | 114,30 (4,50) | 139,70 (5,50) |

| Ichki diametrli ID - qutining yelkasi | mm (dyuym) | 60,33 (2,38) | 76,20 (3,00) | 101,60 (4,00) | 101,60 (4,00) | 127.00 (5.00) |

| Devor qalinligi | mm (dyuym) | 6,35 (0,25) | 6,35 (0,25) | 6,35 (0,25) | 6,35 (0,25) | 6,35 (0,25) |

| Pin uchi uzunligi | mm (dyuym) | 63,50 (2,50) | 69,85 (2,75) | 76,20 (3,00) | 63,50 (2,50) | 63,50 (2,50) |

| Ip balandligi | mm (dyuym) | 6,35 (0,25) | 6,35 (0,25) | 6,35 (0,25) | 10,16 (0,40) | 10,16 (0,40) |

| Og'irligi | kg/m (lb/ft) | 11,71 (7,87) | 12,96 (8,71) | 16,95 (11,39) | 16,95 (11,39) | 20.94 (14.07) |

| Koson tarkibi hajmi | L/m (gal/ft) | 4,19 (0,34) | 4,56 (0,37) | 8,11 (0,65) | 8,11 (0,65) | 12,67 (1,02) |

| Teshik hajmi | L/m (gal/ft) | 4,45 (0,36) | 6,62 (0,53) | 10,84 (0,87) | 10,84 (0,87) | 16.18 (1.30) |

| Koson/teshik halqasi hajmi | L/m (gal/ft) | 0,27 (0,02) | 0,41 (0,03) | 0,58 (0,05) | 0,58 (0,05) | 0,85 (0,07) |

| Minimal rentabellik kuchi | MPa (psi) | 524.00 (76000.00) | 524.00 (76000.00) | 524.00 (76000.00) | 524.00 (76000.00) | 524.00 (76000.00) |

| Minimal kuchlanish kuchi | MPa (psi) | 599,84 (87000,00) | 599,84 (87000,00) | 599,84 (87000,00) | 599,84 (87000,00) | 599,84 (87000,00) |

| Siqilish hajmi | L/m (gal/ft) | 1,33 (0,11) | 1,65 (0,13) | 2,15 (0,17) | 2,15 (0,17) | 2,66 (0,21) |

| Portlash bosimi - qutining elkasi | MPa (psi) | 30,30 (4394,78) | 24.24 (3515.00) | 19,56 (2837,33) | 14,98 (2172,33) | 12,25 (1777,36) |

| Portlash bosimi - o'rta tana | MPa (psi) | 79,74 (11565,22) | 65,50 (9500,00) | 50,94 (7388,89) | 50,94 (7388,89) | 41,68 (6045,45) |

| Yiqilish bosimi - o'rta tana | MPa (psi) | 72,81 (10559,55) | 60,82 (8821,43) | 48,11 (6978,40) | 48,11 (6978,40) | 39,79 (5770,66) |

Standart geometrik ma'lumotlar ISO 10097-2 xalqaro standartida tavsiflangan nashr etilgan sanoat qiymatlariga asoslanadi.Ba'zi qayd etilgan qiymatlar TDS muhandislik bo'limi tomonidan hisoblab chiqilgan.G'amxo'rlik va ishlov berish, shuningdek, burg'ulash sharoitlari, amaliyotlar va ishlatiladigan uskunalar ham yakuniy quvvat va ishlashda muhim rol o'ynaydi.

Xabaringizni shu yerga yozing va bizga yuboring